Overview:

Originally developed by JPC (Japan Pipe Conveyor), DG pipe-type belt conveyor (hereinafter referred to as pipe belt conveyor) was first put into practical use, and then other Japanese companies such as Bridgestone, Tokai (East China Sea), Mitsubishi (Mitsubishi), Yoshino Rubber (Yoshino Rubber), also developed their own system of the pipe belt conveyor. Our company is on this basis, from my company's senior engineer, Technical director to lead the company technical team, set the book, set at home and abroad on the pipe conveyor belt technical data in a furnace, independent research and development, innovative design of the Chinese-style pipe conveyor belt, which fully comply with national standards: JB / T10380-2013 "pipe belt conveyor technical conditions"; also better than the Japanese-style pipe conveyor belt. Among them, a number of patented technologies.

Product Features:

(1), DG-type pipe conveyor belt (with tube machine), the conveyor belt close to the ordinary conveyor belt, which is suitable for the user's habits, easy to be accepted by users;

(2), the tube with the whole machine closed transmission, to prevent the external debris mixed with the transport of materials; can also prevent the material subjected to rain or sun and other damage, in principle, to avoid leakage material, sprinkle material, etc., to meet environmental protection Requirements, is a very good environmental transport equipment!

(3), the pipe with the function of flexible layout process design, can achieve a small radius of three-dimensional space (vertical, horizontal plane can turn, you can achieve spatial curve), to avoid the establishment of the intermediate transfer station and the corresponding auxiliary equipment Investment and maintenance costs; especially suitable for space is relatively small, or obstacles in the complex environment of the transmission line construction. Shorten the transmission distance, reducing the construction cost.

(4), with a small width of the pipe machine frame. As a result of circular cross-section conveying material, the tube with a lower width of the machine, to obtain a larger effective transport area under the same conditions, the width direction can be reduced to the original 1 / 3. Thus reducing the civil construction space requirements, reducing the consumption of steel, reducing the cost and working hours.

(5), can achieve a large angle of transmission.General slot conveyor belt inclination angle can only be about 18 °, and pipe machine as the conveyor belt is the material wrapped in the pipe transport, increased between the material and the conveyor belt Friction, so the delivery angle can be up to 30 °.

(6), the two-way material can be conveyed.Because the pipe machine in the load section and the return section are closed tubular structure, so the return section can still transport material.

(7). However, there are some shortcomings in the pipe-belt machine, such as the material and manufacturing requirements of the conveyor belt, the difficulty in determining the main resistance coefficient, the space bending deformation and the complex load, the difficulty in design and calculation, Especially difficult; transmission capacity and the same bandwidth, belt speed compared to a decrease.

DG type belt conveyor main technical parameters (Chinese style)

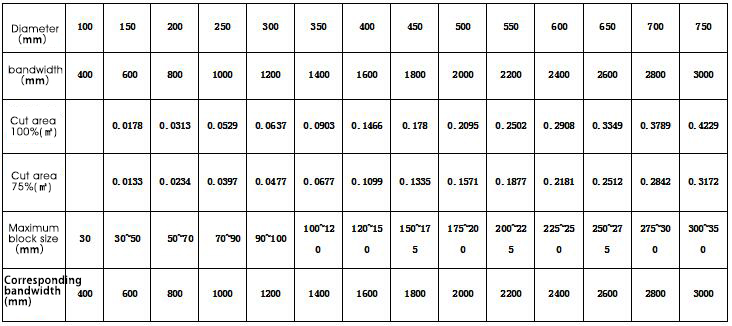

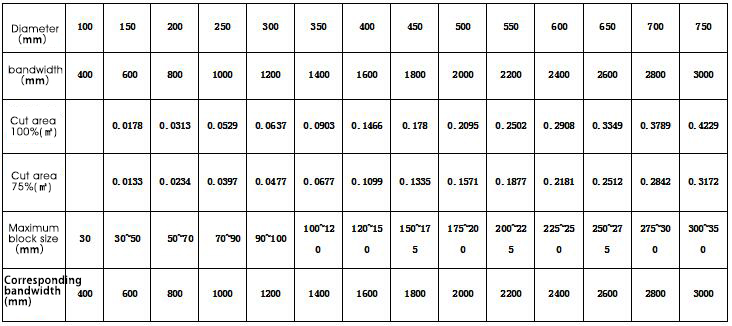

Table 1: The corresponding bandwidth of different diameter, cross-sectional area and allowable block degrees

Table 2: Matching relationship between pipe diameter D, belt speed v and conveying capacity Q (Chinese style)

Please improve your message!