product description

1, the company's DTII, DTII (A) belt conveyor (referred to as belt) is used in the original drawing of the Ministry of Machinery Industry Joint Design Group designed a unified national standard drawing on the basis of part of the optimization design to improve the new drawings Implement GB / T10595-2009 "Belt Conveyor Technical Conditions" and other relevant national standards and JB / ZQ8008-88 "Belt Conveyor Product Quality Classification" and other related testing standards.

2. Products are widely used in building materials, mining, coal, electricity, metallurgy, chemicals, ports, food and other industries; products sell well all over the country, some products exported to Southeast Asian countries and regions, well received by users at home and abroad. The series of products for conveying the material temperature at 50 ℃ (high temperature materials can be specially designed) following the bulk, block or into pieces of goods.

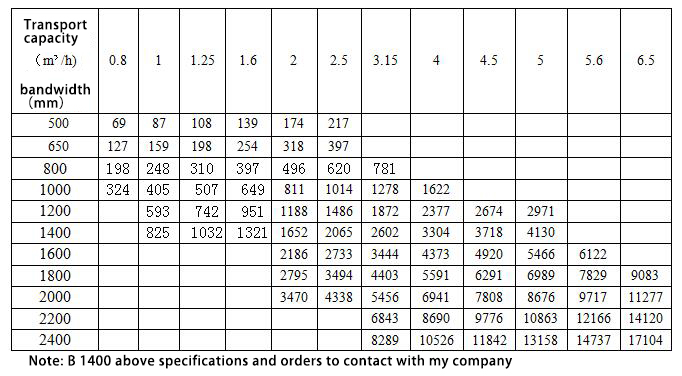

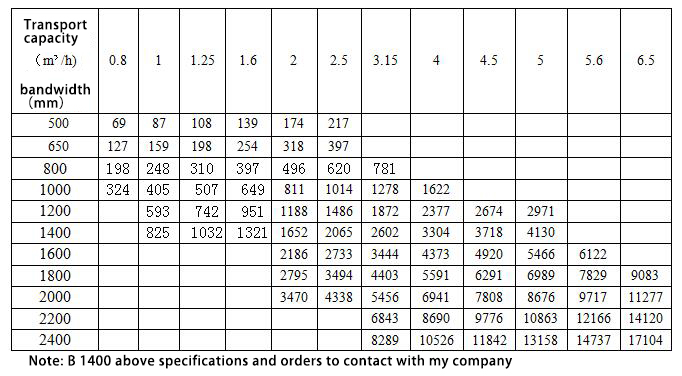

3, flexible layout of the process, diverse: According to the user's actual process needs, can be realized horizontal, tilt, concave, convex arc (vertical plane) curve turns and other combinations of layout; also can achieve single-drive or dual drive (High power, large capacity, long distance) settings; can also achieve the head drive or central drive settings.Can be composed of multiple conveyor level, tilt; transfer (to achieve horizontal turn), in order to achieve a large delivery system . Its maximum capacity of up to 3000m ³ / h.

4, the belt conveyor (referred to as belt) key parts of the processing, manufacturing and assembly are equipped with quality control points, and a special process, tooling to ensure product quality.

5, in the product technology: a perfect process line, machining, material pretreatment, welding, heat treatment and other 15 kinds of necessary technical documents readily available for large rollers, shafts, rollers of the key components of the degree A quality control point was developed.

6, in the tooling, the mold: the company after a lot of input and well-designed to complete the B500mm ~ B1400mm various types of tooling, mold more than 20 sets (pay) purchased the drum welding automatic rotary machine; self-made roller beam welding tooling And drum static balance frame, roller displacement detection frame, roller dust, waterproof experimental device and so on.

Technical Parameters

Please improve your message!